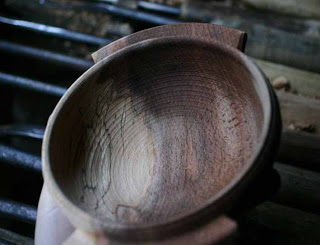

Its been another week of porringer making, I find it most efficient to make just one style of bowl for a couple of weeks then I’ll switch to something else. After a while the body just does the job swiftly and efficiently with little need for conscious thought. At this stage I am free to think about other things and one of the things I have been looking at this week is the character of the toolmarks left on my bowls. Like the old turners and unlike most modern woodturners I use no sandpaper so the finished surface is created by the cutting tool. The tool leaves an image of itself on the wood, if the tool is anything less than razor sharp it will tear the fibres rather than cutting cleanly. Then there is the question of how aggressively I am cutting, if I move the tool rapidly into the wood the marks left are coarse or widely spaced, most of the time for the final cut I keep an especially sharp tool and move it fairly slowly through the wood creating relatively fine clean cut surface.

When I look at medieval bowls I can read the toolmarks and see both how sharp the tool was and how fast the turner was cutting, the bowls I most admire are ones where the toolmarks are very coarse or widely spaced yet still perfectly cleanly cut, this requires the wood to be in perfect condition, the tool to be razor sharp and the technique to be perfect. This week everything worked wonderfully and I approached that ideal with some bowls. In fact I find few people appreciate these coarse toolmarks today and finer tollmarks sell better but to me this is the ultimate in skillful, humble, functional bowl production.

Here is a medieval bowl from Lubeck Germany with lovely toolmarks showing the skill of the turner. I find it interesting that if I make exact replicas of these coarse bowls they do not sell today, there was clearly a different value system at the time.

And a close up of another with even coarser marks. Most folk today would choose finer toolmarks and would not think of eating from a surface like this but in fact the wood is cleanly cut and would wear and clean well.

I have been making my bowls out of a very large old beech tree. It was a street tree in Sheffield and was taken down when it became dangerous. I bought it from the tree surgeons and cut it into large rings so that I could fetch them home in my trailer. Once it’s cut into rings the wood starts drying out and if it dries too quickly before I have made it into bowls it can split, that was not a problem last week with the rain but yesterday was very windy and wind dries things much faster than any amount of heat so I had to bury the rest of the tree in wet shavings to keep it from drying out and splitting over the weekend…hopefully it will still be OK on Monday when I’ll cut it up into bowl blanks.

I’ll bet the ridges on the inside of the bowl are great for keeping gravy in a bowl until it gets swept out by a piece of bread. Yum.The thing about modern bowls, too, is that they are meant to be set on a table and not to be moved–a medieval bowl would probably be picked up and carried.

You know that is a very perceptive comment, I had been making bowls and studying medieval ones for quite a few years before I realised they were all designed to be hand held, very few folk ever ate at a table. An interesting thing is that now many folk are reverting to eating off their knee in front of the TV a big wooden dish is again better than a flat pottery plate. Keeps your food warm and your lap cool, I am still a fan of family dinners around the table though.

I’m cheating, a bit–I have a graduate degree in medieval studies, but it is all in literature and language, with a smattering of culture and history. I’ve been trying to find instances of manuscript illustration where the bowls are placed on the table, but it seems to be most popularly in royal scenes or in extremely late-medieval examples of upper middle class feasts. I confess I use my bowl to eat breakfast in front of my computer as I check my online classes, and at lunch walking around the kitchen as the things I am cooking for our family dinner settle down to simmer/rise/bake. We’re adamant about sit-down dinners, as well, but it is a concession that while most people are at work or school I can at least use nice dishes while I hurry around trying to prepare for a warm home.Maybe it was medieval practice to use them for children, like we still do in some places?

Most of the manuscripy illustrations of dining scenes are high class. There are bowls in things like the Lutteral Psalter, in fact there is a monk drinking from a silver rimmed mazer. Also on the Bayeux tapestry, its a real shame we have no images of normal dining until Breugal and other artists in the low countries, there we see wooden bowls being the standard eating vessel for peasants as they were no doubt centuries earlier. There are virtually no ceramic bowls dishes or plates from the medieval period only cooking pots, storage jars and jugs.

[…] skill to pull off this sort of historically accurate imperfection. Robin Wood can do it with his medieval bowls and spoons. Peter Follansbee can do it with his colonial chests and joint stools. But both of them have more […]