Then to the clicking and closing room, here the leather is cut out using the best parts of the hide for the areas of high stress in the boot. These are actually bits for traditional leather cycling shoes for retro cyclists.

Pat does the closing, that is stitching the various bits of the upper together, and she has been doing it here for over 50 years!

It’s a lovely old sewing machine, quietly and accurately stitching through two layers of really tough boot leather.

lots of lasts

downstairs now and these are tough workboots having the sole and upper united.

workboot uppers

These work boots are now ready to have rubber soles cast on to them. The rubber has a shelf life of 2 weeks and a big minimum order quantity so they have to build up a large stock then spend a week just doing rubber soles.

This machine casts the sole.

lasts

Now on to leather soled boots, I ordered a pair of these. This amazing sewing machine is stitching through nearly 1/2 an inch of leather.

This machine is fed with brass rood cut with a screw thread, it basically screws the leather sole and upper together more securely even than the famous good year welted sole. These are tough boots and will hold together even if they get worn down past the stitching.

a bott with vibram sole, if you click to expand this image you may be able to see that as well as the heavy stitching there is that row just inside of brass screwws holding it all together.

Hobnails! This pair of boots are in for repair, not what I would call a repair, basically all that is original is the uppers they have had complete new soles, lots of hand fitted hobnails and metal horseshoes front and back, they are not as good as new they are better than new because the uppers are already worn in to fit the user. I ordered horseshoes on mine but not the hobnails, they really are very noisy and pretty skiddy on a hard surface.

Another pair of boots in for the re-soling treatment. I love that they do this, I give footwear a hard life and wear boots out, my new boots will be paying intermittent visits to the place they were made for many years to come.

Here is my mate Andy choosing the leather for his boots, they don’t normally offer this degree of customisation and having seen Andy dithering over all the potential options I can understand why.

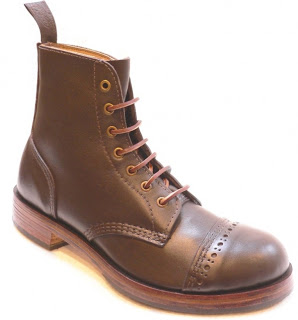

Here are a bunch of boots ready to go, I think these are maybe the “Tan waxy leather sole boot” I love that the Lennon’s website quotes prices including vat and delivery and a pair of these tough stylish made in England boots costs just £150 delivered. They are apparently all the rage in Japan and with tweedy city folk, I am definitely a new fan.

I should show you the outside fo the mill, a typical Derbyshire limestone mill building, Can you imagine what it feels like to be working making boots in the same building four generations of your family have worked in? I love to see small scale manufacturing going on within local communities like this it just feels healthy and right somehow. Andy bought the mens traditional Derby boot

Nice tour, Robin. I love seeing these crafts and economies kept alive. True hope for a sensible future. This reminds me of the US shoemaker Russell Moccasin, whom I own a pair of boots from. Craftsmanship that is hard to find…

That looked to be a great tour. I am so glad to see that we still have a company like this producing some really well made items, at what is still a very reasonable price for what you have in the end.

I have had a pair of boots from William Lennon, and can certainly testify to the superb build quality of them, having nicely worn in over a couple of years, but show no signs of ever wearing out. I guess eventually they will need re-sole ling, but not any time soon that is for sure!